Blog

5 Axis Machining Advantages for Precision Manufacturing in 2023 The Ultimate Guide

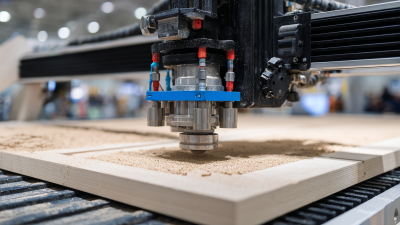

In the rapidly evolving landscape of precision manufacturing, 5 axis machining stands out as a revolutionary technology that is reshaping the industry in 2023. With its capability to create intricate geometries and complex designs, 5 axis machining enhances productivity and accuracy, making it an essential process for manufacturers aiming to stay competitive. According to John Smith, a leading expert in the field, "5 axis machining empowers manufacturers to achieve unprecedented levels of precision, enabling them to tackle the most challenging designs with ease." This powerful technique not only maximizes tool efficiency but also reduces material waste, making it a sustainable choice for modern manufacturing.

As we delve into the ultimate guide to 5 axis machining advantages, it becomes clear that understanding its benefits is crucial for businesses looking to innovate and excel in a highly competitive market. From aerospace to automotive, industries across the board are increasingly recognizing the importance of integrating advanced machining methods. The insights gained from examining the top advantages of 5 axis machining can serve as a valuable resource for manufacturers seeking to elevate their production capabilities and meet evolving client demands. Through this exploration, we aim to highlight how embracing 5 axis machining can lead to transformative improvements in precision manufacturing practices.

Benefits of 5 Axis Machining for Enhanced Precision in Modern Manufacturing

5-axis machining has emerged as a vital tool for enhancing precision in modern manufacturing. This advanced technology allows for the simultaneous movement across five axes, enabling the creation of complex geometries that are difficult or impossible to achieve with traditional machining methods. According to a 2022 industry report by Technavio, the global 5-axis machining market is projected to grow by over $700 million by 2025, driven by increasing demand for precision engineering across various sectors, including aerospace and automotive.

One of the primary benefits of 5-axis machining is its ability to significantly reduce setup time and part handling. Traditional 3-axis machining often requires multiple setups to achieve intricate details, but with 5-axis capabilities, manufacturers can produce highly detailed components in one go. This not only streamlines the production process but also minimizes the risk of errors and maintains tighter tolerances. A study from the International Journal of Advanced Manufacturing Technology indicates that companies utilizing 5-axis machining can achieve tolerances as tight as ±0.02 mm, which is crucial for applications requiring high precision. As industries continue to demand greater accuracy and efficiency, embracing 5-axis machining becomes essential for staying competitive in the marketplace.

5 Axis Machining Advantages for Precision Manufacturing in 2023

| Advantage | Description | Impact on Manufacturing |

|---|---|---|

| Increased Precision | Allows for complex geometries and tight tolerances in part manufacturing. | Reduces the need for secondary operations, saving time and cost. |

| Enhanced Complexity | Capable of machining intricate shapes that are impossible with traditional methods. | Enables designers to create innovative products with more features. |

| Reduced Setup Time | Minimizes the number of setups required for complex parts. | Increases throughput and efficiency on the shop floor. |

| Improved Tool Life | Optimized cutting angles lead to less wear on tools. | Lowers maintenance costs and provides more consistent production quality. |

| Flexibility | Versatile in handling various materials and part sizes. | Allows for quick adaptation to different production demands. |

Technological Advancements Driving 5 Axis Machining Efficiency

The rapid advancement of digital manufacturing technologies has significantly boosted the efficiency of 5-axis machining, making it a cornerstone of precision manufacturing in 2023. This technology allows for enhanced maneuverability and the ability to produce complex geometries that traditional machining methods struggle to achieve. As a result, industries can now produce more intricate components with improved accuracy and reduced lead times. Innovative software solutions and automation tools have enabled seamless integration with existing manufacturing processes, further optimizing productivity and minimizing waste.

In addition to traditional benefits, recent developments in 5-axis machining facilitate real-time monitoring and data collection, leading to smarter decision-making in production environments. Manufacturers are leveraging these advancements to enhance their competitiveness on a global scale. The shift from merely chasing efficiency to becoming leaders in the high-end machine tool sector underlines the industry's evolution, emphasizing a commitment to quality and innovation.

The emphasis on intelligent manufacturing aligns with broader trends that prioritize sustainability and resource optimization, solidifying 5-axis machining as an essential component of modern manufacturing strategies.

Cost-Effectiveness of 5 Axis Machining in Competitive Markets

The landscape of precision manufacturing in 2023 is increasingly influenced by the cost-effectiveness of 5-axis machining. As per a market research study, the global demand for CNC machining is projected to see a substantial uptick, with the 5-axis CNC machining centers market alone set to grow by approximately USD 792.5 million between 2024 and 2028. This growth is largely attributed to advancements in self-optimized machine cutting processes, which enhance efficiency and reduce waste, thus making 5-axis machining a favorable option for manufacturers striving to remain competitive.

Moreover, the integration of artificial intelligence (AI) in manufacturing processes is revolutionizing the 5-axis machining sector. AI's capabilities in predictive maintenance and real-time monitoring not only streamline operations but also significantly cut down on costs associated with downtime and errors. As companies navigate competitive markets, adopting 5-axis CNC technology combined with AI innovations can result in improved production rates while maintaining high levels of precision. As such, manufacturers are increasingly recognizing the strategic importance of these technologies in their operational frameworks.

Applications of 5 Axis Machining in Various Industries

As we move further into 2023, the applications of 5-axis machining are becoming increasingly vital across various industries. This advanced manufacturing technique allows for complex geometries to be produced with a high degree of accuracy, making it ideal for sectors such as aerospace, automotive, medical devices, and even electronics. The ability to move the cutting tool along five different axes simultaneously enables manufacturers to create intricate parts that would be nearly impossible to achieve with traditional machining methods.

In the aerospace industry, for instance, manufacturers leverage 5-axis machining to produce lightweight yet robust components that meet rigorous safety standards. Similarly, in the medical sector, precision is paramount, and 5-axis machining facilitates the production of intricate surgical instruments and implants. The growth in demand for customized and complex components across these industries drives the expansion of the global machining center market, which was valued at approximately $29.17 billion in 2018 and is projected to grow at a compound annual growth rate of 4.9% during the forecast period. This trend highlights the crucial role of 5-axis machining in meeting modern manufacturing challenges.

Future Trends in 5 Axis Machining for Precision Engineering

The future of 5-axis machining is poised for significant advancements, driven by the adoption of digital manufacturing technologies that enhance productivity across various sectors. According to market research, the United States CNC milling machines market is projected to reach USD 6.5 billion by 2032, indicating a robust growth trajectory that reflects the increasing demand for precision engineering solutions. This growth is particularly evident as industries seek to streamline operations and improve efficiency through innovative machining techniques.

In Europe, the CNC machine market is also on the rise, with expectations of substantial growth by 2033. The market dynamics are shifting as manufacturers leverage advanced 5-axis technology to achieve intricate designs and high precision, which are essential in sectors such as aerospace and automotive. Furthermore, the global CNC metal cutting machine tools market is witnessing an expanding demand, suggesting a favorable environment for investments in advanced machining capabilities. As companies continue to integrate sophisticated tools and processes, the landscape of precision engineering will undoubtedly evolve, setting new standards for quality and efficiency in manufacturing.

Related Posts

-

Uncovering the Advantages of Utilizing CNC Machines in Modern Manufacturing

-

5 Smart Tips for Choosing the Right Small CNC Mill for Your Business Needs

-

Exploring CNC Router Innovations at 2025 China Import and Export Fair 138th Session

-

Revolutionizing Manufacturing: How Industrial CNC Technology is Shaping the Future of Production

-

Understanding the Benefits of 5 Axis Machining for Modern Manufacturing Processes

-

Exploring the Future of Manufacturing with CNC Milling Machines and Their Innovations