KSH Horizontal Machining Center Series

Product Highlights

The KENT USA® KSH-4000P series Horizontal Machining Center integrates proven machine design with cutting-edge control and manufacturing technology. Renowned for their reliability and stability, these machines are a top choice for demanding job shops and in-house production facilities. The robust machine body structure ensures higher turning efficiency, superior finishes, and longer tool life, significantly enhancing productivity and profitability. Enhance your global competitiveness today.

| KSH-4000P | |

| Travels | |

| Longitudinal Travel X-Axis | 20″ |

| Cross Travel Y-Axis | 20″ |

| Vertical Travel Z-Axis | 20″ |

| Spindle Center to Table Top | 3.15″ Min / 23.2″ Max |

| Spindle Nose to Table Center | 2.75″ Min / 22.8″ Max |

| Table Height from Floor | 43.3″ |

| Pallet | |

| Pallet Working Surface | 15.7″ x 15.7″ |

| Max Workload on Pallet | 880 lbs. |

| Table Surface | Qty 25 – M16 Holes |

| Max Workpiece Size (∅ / height) | 21.65″ x 31.5″ |

| B-Axis Contour Positioning (full 4th axis) | .001° |

| Spindle | |

| Spindle Motor | 50HP / 35HP 30 min. / 25HP cont. (built-in) |

| Spindle Taper | Big Plus CAT-40 / BT-40 / HSK-63A |

| Spindle Drive System | Integral Motor |

| Spindle Speed | 0 – 15,000 RPM |

| Spindle Torque | 184 ft./lbs. @ 980 RPM |

| Spindle Bearings | Hybrid Ceramic with Air/Oil Mist Lubrication |

| Automatic Tool Changer (Standard) | |

| Number of Tools | 60 |

| Tool Selection | Random |

| Tool Change Time | 1.4 sec. Tool to Tool |

| Chip to Chip Time | 2.6 sec. Chip to Chip avg. |

| Max Tool Diameter | 3.15″ with Adjacent Tools 6.6″ without |

| Max Tool Weight | 26.4 lbs. |

| Max Tool Length | 11.8″ |

| APC Unit ( option) | |

| Type | Rotary (0 – 180°) |

| Change Time | 5.9 sec. |

| Rotation Method | Servo Motor |

| Pallet Clamping Method | Ball Lock Cones – 37,400 lbs. Clamp Force |

| Ballscrews and Axis Motors | |

| X-Y-Z Ballscrew Diameter | 40mm (1.57″) x 16mm Pitch |

| Ballscrew Type | Class 3 Double Nut Pre-loaded |

| Ballscrew Mounting Type | Pre-tensioned/Double Anchored |

| X-Y-Z-B Servo Motor HP | 5.2 – 9.0 – 5.2 – 2.1 HP |

| Servo Motor Mounting | Direct Coupled |

| Feeds | |

| Rapid Traverse Rate X, Y, Z | 2,362 IPM |

| X, Y, Z Acceleration | 1G |

| Cutting Feed Rate | 0.01 – 787 IPM |

| Positioning Accuracy | ± .0002″ Full Stroke |

| Repeatability | ± .0001″ |

| General | |

| Coolant Tank Capacity | 120 Gallons |

| Machine Weight | 23,000 lbs. |

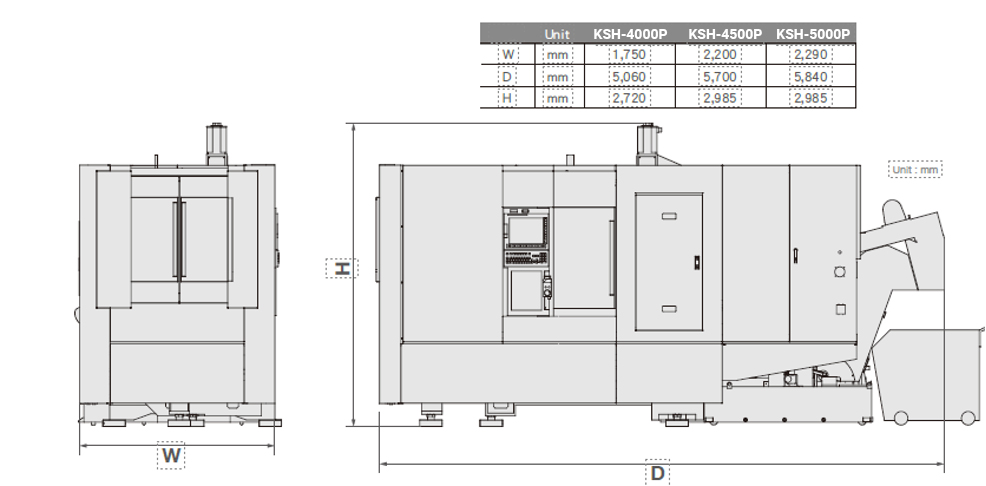

| Floor Space | 209″ x 69″ x 107″ |

| Machine Power Source | 208/220 Volts, 3 Phase 150 Amps |

| Air Source | 90 PSI |

- Fanuc 0i-MF Plus, 10.4’’ LCD

- 15,000 rpm (built-in), 37/26/18.5KW (50HP / 35HP/25HP)

- CAT-40

- Spindle cooler

- 20 Bar CTS

- 001degree B axis

- ATC: 60Tools

- Integrated Chip Conveyor + trolley

- Oil Skimmer

- Coolant gun

- Air gun

- Pallet 400 x 400 mm (15.7 X 15.7”)

- part dim. ⌀ 550 x H800 mm (Ø21.65″ x 31.5″)

- X/Y/Z stroke 510 / 510 / 510 mm (20 x 20 x 20”)

- X/Y/Z rapid 60/60/60 m/min (2,362ipm)

- tool length 300 mm (12”)