Blog

Top 5 Axis CNC Mill Buying Guide for 2025 Essential Features and Tips

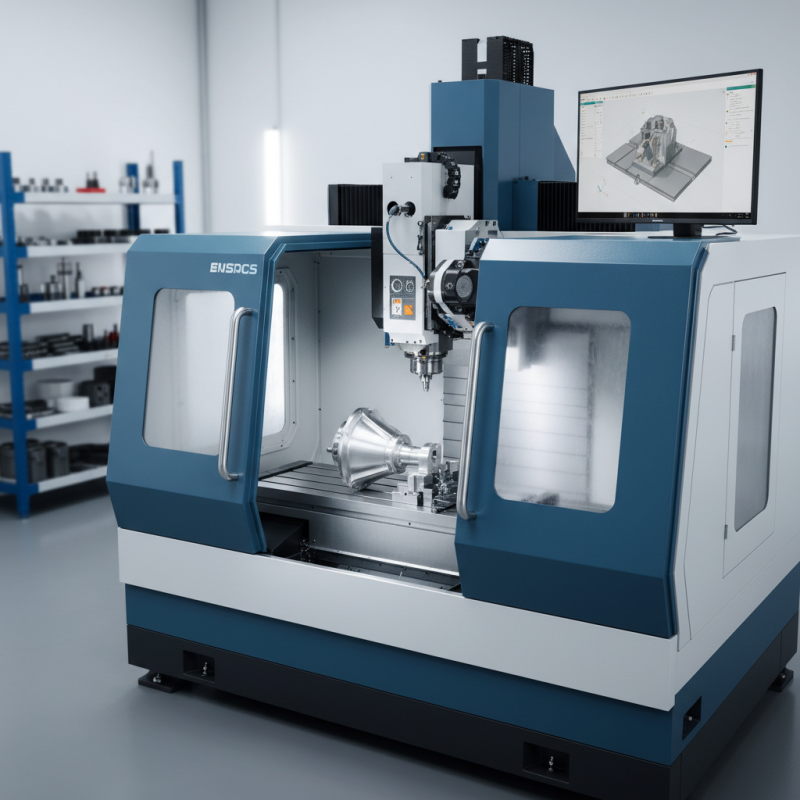

When it comes to precision machining, the 5 axis CNC mill stands out as a crucial tool for modern manufacturing processes. As industries continue to evolve, the demand for machines that offer unparalleled accuracy and versatility has surged, making it essential for both seasoned professionals and newcomers to understand what to look for when buying a 5 axis CNC mill. This buying guide for 2025 will delve into the essential features, performance parameters, and practical tips that can help you make an informed decision.

Investing in a 5 axis CNC mill is significant, given its complexity and the wide array of options available on the market. Understanding the key features such as axis movement capabilities, control systems, and tooling compatibility can empower you to select a machine that aligns with your operational requirements. Moreover, considerations around the machine's size, stability, and customer support resources can greatly influence your overall satisfaction and productivity. As we explore this guide, you will gain insights that not only foster a deeper understanding of these advanced machines but also arm you with the knowledge necessary to navigate your purchasing journey effectively.

Understanding the Definition and Benefits of Axis CNC Mills

Axis CNC mills, known for their precision and versatility, are integral to various manufacturing sectors, including aerospace, automotive, and medical device production. Understanding the definition and benefits of these specialized machines is vital for industries aiming for efficient and high-quality output. CNC, or Computer Numerical Control, allows operators to accurately dictate the movements of machines, maintaining tight tolerances and enhancing repeatability over manual processes. According to a recent industry report from MarketsandMarkets, the global CNC machine market is projected to grow from $70.77 billion in 2021 to $102.54 billion by 2026, indicating an increasing reliance on CNC technology in modern manufacturing.

The benefits of utilizing axis CNC mills are manifold. These machines facilitate a significant reduction in human error and production time while improving product quality. For instance, a report by Technavio highlights that manufacturers adopting CNC milling can improve production time by up to 50%, compared to traditional machining methods. Furthermore, the multi-axis capabilities of these mills allow for the creation of complex geometries and components in a single setup, minimizing the need for multiple tools and setups, which can lead to cost savings and enhanced production efficiencies. Given the rapid advancement in CNC technology, understanding these benefits is crucial for businesses aiming to stay competitive in a fast-evolving market landscape.

Key Features to Consider When Buying an Axis CNC Mill

When purchasing an axis CNC mill, several key features should be prioritized to ensure optimal performance and efficiency. First and foremost, consider the size and travel capacity of the machine. This will directly impact the types of projects you can undertake, including the dimensions of materials you can work with. A larger travel capacity offers more versatility, but it is essential to balance this with the available space and intended applications in your workshop or manufacturing facility.

Another critical feature to look for is the spindle speed and power. A high spindle speed allows for faster cutting and can accommodate a wider range of materials, from soft plastics to hard metals. Additionally, machine rigidity plays a crucial role in achieving precise cuts and maintaining durability over time. Look for mills that feature robust construction materials and designs to enhance stability and reduce vibration during operations. Lastly, user-friendly controls and software compatibility are essential for simplifying programming and enhancing productivity, especially for those who may be transitioning from manual machines to CNC technology.

Top 5 Axis CNC Mill Buying Guide for 2025: Essential Features and Tips

This chart represents the key features to consider when buying an Axis CNC Mill in 2025, rated on a scale from 1 to 10 based on their importance. Precision is the most critical feature, followed by speed, ease of use, and durability, while cost is relatively less important.

Comparing Different Types of Axis CNC Mills Available in 2025

When exploring the various types of axis CNC mills available in 2025, it's important to understand the fundamental differences that can affect your machining needs. The most common types include 3-axis, 4-axis, and 5-axis CNC mills. The 3-axis CNC mill is ideal for simple machining tasks, as it moves along the X, Y, and Z axes. This type is often favored for straightforward projects where precision cuts on flat materials are required.

On the other hand, 4-axis mills introduce an additional rotational axis, allowing for more complex operations. This capability enables users to work on multiple sides of a piece without needing to change setup, significantly enhancing efficiency and accuracy. For the most advanced machining, 5-axis CNC mills offer unparalleled versatility, allowing movement along all five axes simultaneously. This allows for intricate designs and shapes to be achieved in a single setup, making them suitable for high-precision work in fields such as aerospace, automotive, and medical tools.

When making a decision on which type of CNC mill to invest in, consider the complexity of the projects you intend to undertake. Assessing factors such as the materials you'll be working with, the precision required, and the overall production volume can help guide you toward the best solution for your machining needs in 2025.

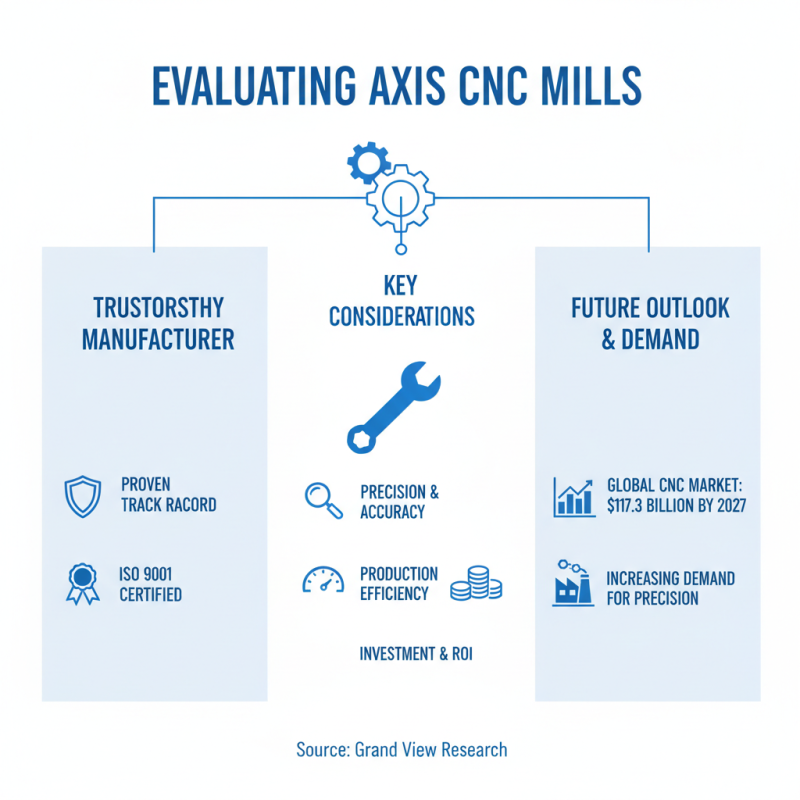

Tips for Evaluating Manufacturers and Models of CNC Mills

When evaluating manufacturers and models of axis CNC mills, it’s crucial to consider several key factors that can significantly impact your investment and production efficiency. According to a report by Grand View Research, the global CNC machine market is projected to reach $117.3 billion by 2027, largely driven by the increasing demand for precision manufacturing in various industries. Therefore, identifying a trustworthy manufacturer with a proven track record is imperative. Look for companies that comply with recognized industry standards, such as ISO 9001 certification, which indicates a commitment to quality management systems.

Additionally, assess the technical specifications of the CNC mills under consideration. Key features include spindle speed, feed rates, and axis movement capabilities. A study from MarketsandMarkets highlights that the ability of CNC machines to perform multitasking operations greatly enhances productivity. It's essential to evaluate the specific requirements of your operations and match them with the technical offerings of the mill. Engaging with customer reviews and case studies can also provide insights into the performance and reliability of different models, helping to make a more informed decision.

Maintenance and Support: Ensuring Longevity for Your CNC Mill

Proper maintenance and support are critical for ensuring the longevity of your CNC mill. Regular maintenance routines, including cleaning, lubrication, and inspections, help prevent wear and tear that can compromise machine performance. Establishing a consistent schedule that includes checking for loose components, ensuring proper lubrication levels, and cleaning chips and debris from the mill can significantly extend its lifespan. Furthermore, understanding the specific maintenance needs of your CNC mill can assist in avoiding costly repairs and downtime.

In addition to routine maintenance, having a reliable support system in place is essential for effective operation. This includes training for operators to effectively utilize the machine and troubleshoot common problems. Building a relationship with experienced technicians who can provide guidance and support is invaluable. Comprehensive service agreements that cover not only maintenance but also parts replacement can also be advantageous. By investing in these support mechanisms, operators can ensure smooth operations and reduce the likelihood of unexpected failures, ultimately maximizing productivity and enhancing the overall performance of the CNC mill.

Related Posts

-

How to Choose the Best Small CNC Machine for Your Business Needs

-

How to Optimize Your Production Efficiency with Fast CNC Machining Techniques

-

The Evolution of CNC Routers Transforming Modern Manufacturing Processes

-

Exploring the Future of CNC Machining Parts in Modern Manufacturing Techniques

-

What is a Mini CNC Mill and How Can It Transform Your Machining Process

-

Understanding the Benefits of 5 Axis Machining for Modern Manufacturing Processes