Blog

Best Small CNC Mill for Beginners and Hobbyists?

For beginners and hobbyists, finding the best small CNC mill can be quite a challenge. The market is flooded with options, each with unique features. A small CNC mill can transform your creative ideas into reality. However, not all machines are suitable for newcomers. It's essential to consider several factors before making a decision.

One critical aspect is ease of use. Many small CNC mills come with complex interfaces. This complexity can overwhelm new users. A more intuitive machine often leads to better productivity. Additionally, the size and affordability of a small CNC mill are vital for hobbyists with limited space and budgets. Think about your projects and space carefully.

While many machines boast advanced features, beginners may not need all of them. It's easy to get caught up in the allure of high-tech capabilities. Reflect on your actual needs and skill level. Selecting the right small CNC mill should ultimately enhance your experience, not complicate it.

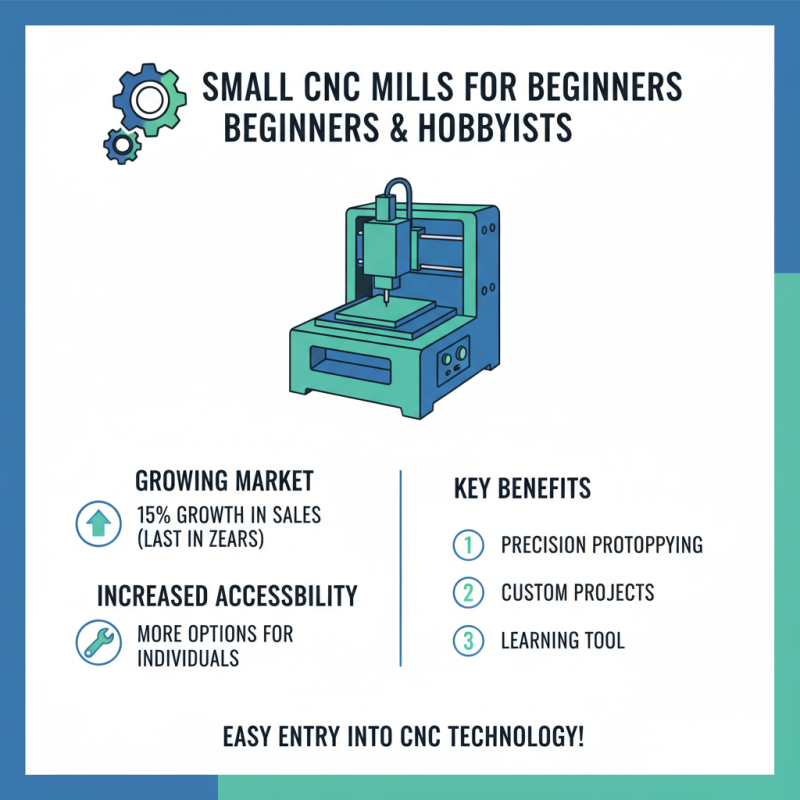

Understanding CNC Mills: What Makes a Small CNC Mill Ideal for Beginners

When considering small CNC mills, it's essential to understand what makes them suitable for beginners. These machines often feature user-friendly interfaces. This encourages new users to explore their capabilities without feeling overwhelmed. A recent report states that over 60% of beginners choose CNC mills due to their versatility and ease of use. A simplified setup process can significantly lower the entry barrier.

Small CNC mills should also offer adequate support resources. Accessibility to tutorials and community forums is crucial. Beginners often face challenges, like calibration and tool selection. According to industry surveys, nearly 40% of new users encounter initial setbacks. A mill that provides clear guidance can help mitigate frustration. This fosters a positive learning experience and encourages creativity.

Another aspect to consider is the machine's work area. A compact design is beneficial for hobbyists with limited space. However, a smaller work area may limit project scope. Users often need to balance machine size with project ambitions. A thoughtful approach can lead to better outcomes and skill development. Ultimately, choosing the right small CNC mill requires careful reflection on personal needs and limitations.

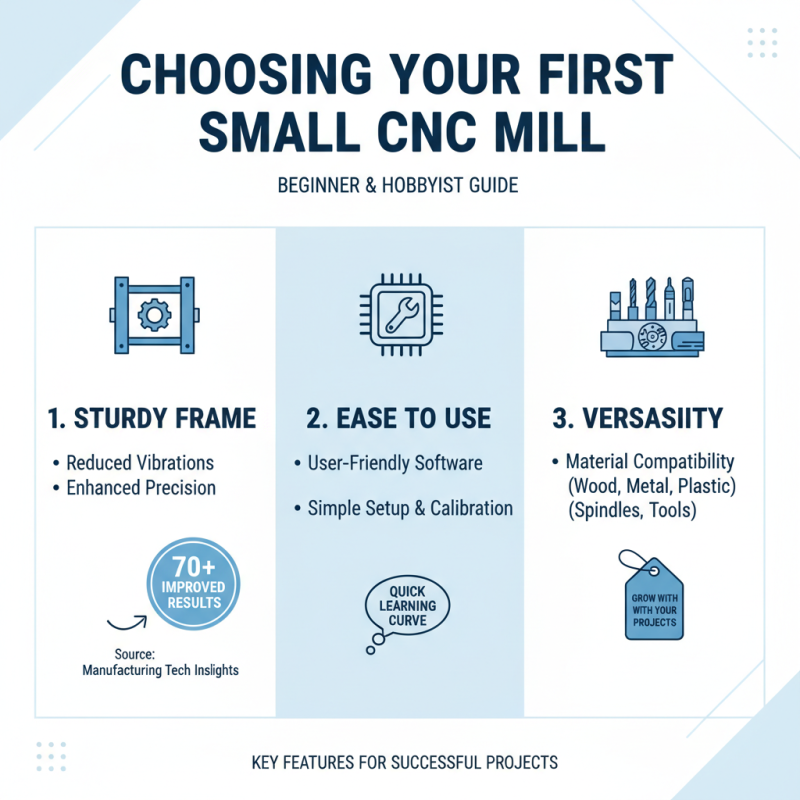

Key Features to Look For in a Small CNC Mill for Hobbyists

Choosing the right small CNC mill is crucial for beginners and hobbyists. The market is filled with various options, but certain key features can make a significant difference in your experience. Many professionals agree that a sturdy frame is essential. A rigid design minimizes vibrations and enhances precision in your projects. In a study by Manufacturing Tech Insights, over 70% of users report improved results with solidly built machines.

Another vital aspect is the milling capacity. A mill that can handle materials like aluminum and wood allows for greater versatility. Many hobbyists prefer versatile machines that can work on multiple materials. It is important to consider the bed size, too. A larger bed facilitates more extensive projects, but some users struggle with space constraints in their workshops. Consulting feedback from research studies shows conflicting opinions; some enthusiasts prioritize compact mills for limited spaces.

Additionally, ease of use cannot be overlooked. A user-friendly interface significantly reduces the learning curve. Some machines come with basic software that simplifies the process, making them more accessible. Yet, many beginners find these software options lacking in features. It is a reminder that you need to research before committing. Many users ultimately emphasize the importance of practical experience over features alone. The real test is how well it fits your specific needs.

Top Recommendations for the Best Small CNC Mills on the Market

When searching for the best small CNC mills, beginners and hobbyists face many options. The market has expanded remarkably, with a recent industry report indicating a 15% growth rate in CNC machine sales over the past two years. This surge highlights the increasing accessibility and interest in CNC technology among individuals.

Tip: Consider your project needs. Some mills excel at soft materials, while others can handle metals. Research the specifications to find the right fit.

Small CNC mills vary significantly in features and capabilities. Many offer user-friendly interfaces, suitable for novices. However, they may lack advanced features that experienced users require. Reports suggest that while ease of use is essential, precision cannot be compromised. Therefore, it’s crucial to balance these aspects when making a choice.

Tip: Always read user reviews. They provide insights into performance issues and reliability. Learning from others’ experiences can save you time and frustration.

Ultimately, carefully evaluating each option will ensure you find a CNC mill that suits your skills and projects. It's a process that benefits from reflection and testing. Embrace the journey of selecting the perfect tool for your creative endeavors.

Cost Considerations and Budgeting for Your First CNC Mill Purchase

Purchasing your first CNC mill can be exciting yet challenging. Cost considerations are crucial. A report from the Association for Manufacturing Technology indicates that small CNC mills typically range from $2,000 to $10,000. This range can be daunting for beginners, especially when factoring in additional costs. Budgeting requires not only the initial price but also software, tooling, and maintenance expenses.

Many hobbyists overlook these hidden costs. Additional accessories can easily add $1,000 or more to your total. Software licenses, which are essential for operation, often come with their own price tags. A basic CAD or CAM software can cost anywhere from $300 to $3,000. Maintenance, too, is a recurring expense that shouldn't be ignored. You might need spare parts or calibration tools regularly.

Reflection is essential when making your budget. What are your long-term goals? Will you be using this mill frequently or just occasionally? Deciding on these aspects will help you allocate your budget wisely. Mistakes in budgeting can lead to dissatisfaction later on. Understanding your needs will keep costs manageable and may prevent buyer’s remorse.

Best Small CNC Mill for Beginners and Hobbyists - Cost Considerations and Budgeting for Your First CNC Mill Purchase

| Model | Price Range | Machine Type | Working Area (mm) | Precision (mm) | Control Type | Features |

|---|---|---|---|---|---|---|

| CNC Mill A | $1,200 - $1,500 | Vertical | 300 x 200 x 200 | 0.01 | USB | Auto Tool Change, LCD Screen |

| CNC Mill B | $800 - $1,200 | Horizontal | 400 x 250 x 200 | 0.02 | PC Software | Compact Design, Easy Assembly |

| CNC Mill C | $1,000 - $1,800 | Vertical | 250 x 150 x 150 | 0.05 | Standalone | Lightweight, Ideal for Small Parts |

| CNC Mill D | $900 - $1,400 | Benchtop | 350 x 200 x 180 | 0.03 | G-code | User-friendly, Bluetooth Connectivity |

Essential Accessories and Software for New Small CNC Mill Users

When starting with a small CNC mill, having the right accessories can make a big difference. Basic tools like clamps and vices help secure the material. Dust extraction systems are also important to keep the workspace clean and safe. Don’t forget about a good set of cutting tools. Quality bits can change the outcome of your project. They are essential for achieving precision and smoother finishes.

Software is another area where beginners often struggle. User-friendly CAD software can simplify the design process. It's vital to choose one that fits your skill level. Some programs even offer tutorials to guide you. Don’t hesitate to experiment with various settings. The first attempts might not be perfect, but that’s part of the learning curve.

Moreover, consider investing in a digital caliper. It can significantly improve measurement accuracy. Calibration tools are also necessary for ensuring the CNC mill runs smoothly. However, many newcomers overlook these essentials. Mistakes will happen, and that’s okay. Each error provides valuable lessons for the next project. Embracing these challenges fosters growth in your CNC journey.

Related Posts

-

5 Smart Tips for Choosing the Right Small CNC Mill for Your Business Needs

-

The Future of Small CNC Mills in Precision Manufacturing with Industry Insights

-

Uncovering the Advantages of Utilizing CNC Machines in Modern Manufacturing

-

7 Incredible Advantages of Using CNC Router Machines for Your Business

-

Exploring CNC Router Innovations at 2025 China Import and Export Fair 138th Session

-

Exploring the Future of Manufacturing with CNC Milling Machines and Their Innovations