Blog

Tips for Choosing the Best Machined Parts for Your Project?

Choosing the right machined parts for your project can be challenging. Many factors come into play when making this decision. Quality is paramount. Poorly made machined parts can jeopardize the entire project.

Consider the material used in the machined parts. Different materials offer varying benefits. Some are stronger but heavier, while others are lightweight yet less durable. Explore your project's specific needs.

Don't overlook the importance of precision. Even minor errors can lead to significant issues down the line. Ensure that the supplier has a good reputation for accuracy. Seek reviews and testimonials. This process can be daunting, but reflecting on these elements will lead to better decisions.

Understanding Your Project Requirements for Machined Parts

When selecting machined parts, understanding your project requirements is crucial. Consider the function of each part. Will it endure stress or operate under extreme conditions? The type of material often dictates performance. For example, lightweight aluminum may be suitable for low-stress applications, while steel offers strength for heavy-duty use.

The manufacturing process also matters. CNC machining can achieve tighter tolerances compared to traditional methods. Reports indicate that parts made with CNC often have a 20% lower failure rate due to their precision. However, this can lead to increased costs. It's essential to balance between precision and budget constraints.

Don't overlook the importance of surface finish. A rough surface can impact the functionality of a part. For instance, a raw surface may cause friction, which affects mechanical components. It's helpful to review manufacturer specifications to find the right balance. Yet, even with clear data, personal judgments can lead to miscalculations. Identifying your needs is key, even when it feels challenging. Every project is unique, and the right machined part must reflect that.

Evaluating the Material Options for Machined Components

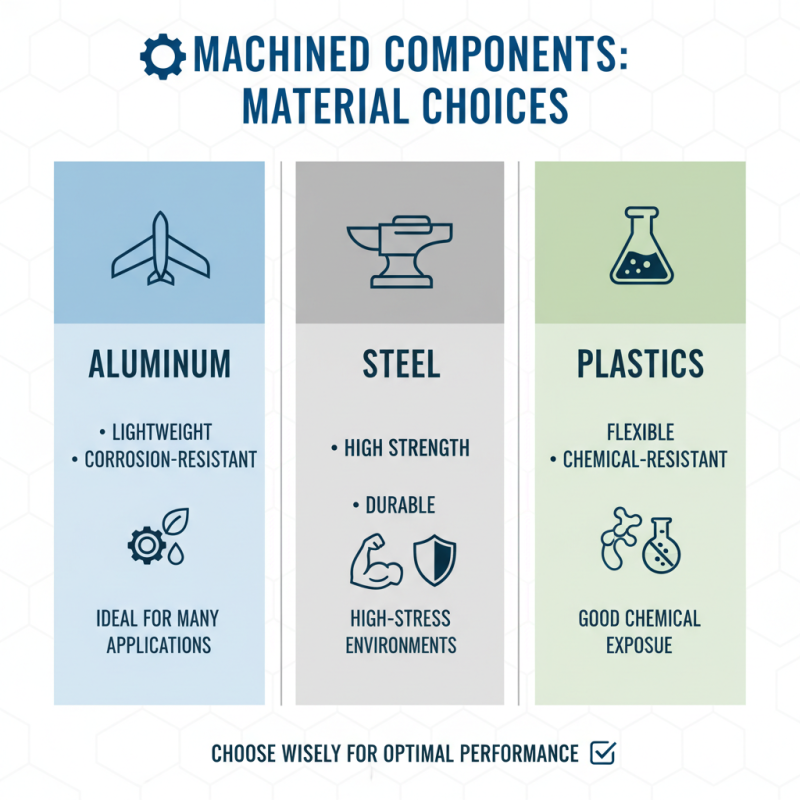

When selecting machined components, material choice plays a critical role. Common materials include aluminum, steel, and plastics. Aluminum is lightweight and corrosion-resistant, making it ideal for many applications. Steel, known for its strength, is often used in high-stress environments. Plastics can offer flexibility and resistance to chemicals but may lack strength.

Each material has its pros and cons. While aluminum is easier to machine, it may not handle heavy loads well. Steel can be challenging to machine due to its hardness. Plastics might warp under heat, which can compromise precision. Understanding these factors is essential for your project’s success.

Additionally, consider the environment where the parts will operate. Will they face extreme temperatures or exposure to chemicals? This affects material longevity and performance. Testing materials in your specific conditions helps clarify choices. It might be wise to prototype with different materials first. This future-proofing could save you time and resources later. Evaluate all options carefully before making decisions.

Considering Tolerances and Specifications in Machined Parts

When selecting machined parts, tolerances and specifications are crucial. Tolerances define the permissible limits of variation in a part’s dimensions. A tight tolerance can ensure precision, especially for components that must fit well with others. However, achieving tight tolerances can increase costs. Balancing precision with budget constraints is a common challenge in manufacturing.

Specifications detail the materials, finishes, and performance standards required for the parts. It’s essential to understand the application before finalizing these specifications. For example, a high-stress component may need a stronger material. Conversely, parts used in less demanding applications may allow for more flexibility. A mismatch between specified materials and actual use can lead to failure.

It’s easy to overlook the finer details. Rushing through this step could result in costly mistakes. Verify how tolerances impact the assembly process. Consider how slight variations can affect performance in real-world conditions. Reflecting on these factors can lead to better decision-making and project success.

Assessing Manufacturing Processes and Techniques for Your Needs

When choosing machined parts, the manufacturing process plays a critical role. Each technique offers distinct advantages. For instance, CNC machining provides high precision and repeatability. It’s perfect for complex parts but can be costly for small batches. In contrast, additive manufacturing allows for innovative designs but may struggle with material strength. Understanding these nuances is essential for making the right choice.

Evaluate your project needs carefully. Consider the material requirements. Some processes excel with metals, while others might be better suited for plastics. Think about tolerances and surface finishes as well. A part with a rough finish may require more post-processing, increasing your overall budget. Reflect on your project timeline too; some methods take longer than expected. It’s a good idea to communicate clearly with potential manufacturers about these factors.

There’s always a learning curve in assessing manufacturing processes. You may think you know what you need, but unexpected challenges can arise. Be open to suggestions from experts. They can offer insights that might change your approach. Embrace the idea that your initial plans may not be perfect. Continuous assessment will help you refine your choices for the best outcome.

Choosing the Right Supplier for Quality Machined Parts

When selecting a supplier for machined parts, quality is paramount. Data from industry reports highlight that approximately 30% of manufacturing defects stem from poor supplier choices. Evaluating potential suppliers involves more than just price. It's crucial to review their quality control processes. A supplier’s certification, such as ISO 9001, can be indicative of their commitment to quality.

Another key aspect is communication. Suppliers with strong communication skills respond quickly and provide detailed feedback. This often leads to fewer misunderstandings and better project outcomes. Reports suggest that clear communication can reduce delays by up to 20%. Don’t shy away from asking for case studies or references. Learning from others’ experiences can reveal a lot about a supplier’s reliability.

It’s also important to consider the supplier’s production capabilities. Some may claim they can handle high volumes, but when push comes to shove, results may vary. Recall a situation where a seemingly capable supplier failed to deliver on time. That can halt your entire project. Always weigh your options carefully. Test orders can provide insight into a supplier’s true capacity and help mitigate risks before committing to larger orders.

Comparison of Key Factors in Choosing Machined Parts Suppliers

Related Posts

-

Understanding the Benefits of 5 Axis Machining for Modern Manufacturing Processes

-

How to Optimize Your Production Line with Fast CNC Machining Solutions

-

How to Optimize Your Production Efficiency with Fast CNC Machining Techniques

-

Unlocking the Secrets of Fast CNC Machining for Efficient Production

-

Exploring the Future of CNC Machining Parts in Modern Manufacturing Techniques

-

Why Fast CNC Machining is Essential for Modern Manufacturing Efficiency