Blog

The Evolution of CNC Routers Transforming Modern Manufacturing Processes

The evolution of CNC routers has significantly transformed modern manufacturing processes, ushering in an era of unprecedented efficiency and precision. According to a report by MarketsandMarkets, the global CNC machine market is projected to grow from $63 billion in 2020 to $100 billion by 2025, highlighting the increasing adoption of advanced technologies in production environments. CNC routers, in particular, have gained traction across various industries, including woodworking, aerospace, and automotive, due to their ability to automate complex tasks and reduce human error.

As manufacturers continue to seek ways to enhance productivity and streamline operations, the strategic integration of CNC routers is becoming a key factor in driving innovation and maintaining competitive advantage. With advancements in software and machine capabilities, the CNC router is not just a tool but a cornerstone of modern manufacturing, enabling businesses to meet the demands of a rapidly evolving market.

The History of CNC Routers: From Manual to Automated Systems

The journey of CNC routers from manual systems to automated precision machinery represents a significant milestone in the history of manufacturing. Early CNC routers emerged in the 1950s, marking a pivotal shift in how materials were processed. Initially, these machines were operated using punch cards and basic software, which limited their capabilities. However, as technology advanced, the introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) in the 1980s revolutionized the industry, enabling greater precision and efficiency.

According to a report by MarketsandMarkets, the global CNC router market is expected to reach $5.1 billion by 2026, growing at a CAGR of 5.4% from 2021. The evolution continues with innovations in automation, which not only enhance production speed but also reduce operational costs. Today, CNC routers are equipped with advanced features like multi-axis capabilities and real-time monitoring systems. These developments allow manufacturers to produce complex designs and manage production workflows more effectively, thereby transforming modern manufacturing processes into a highly efficient and adaptable landscape.

Key Technological Advancements in CNC Router Design

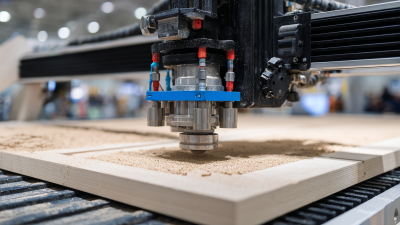

The design of CNC routers has undergone significant technological advancements that have dramatically transformed modern manufacturing processes. One of the key developments is the integration of advanced software capabilities, allowing for more intuitive user interfaces and enhanced design precision. These sophisticated software programs enable operators to easily manipulate complex designs and simulate machining processes in real-time, which minimizes errors and maximizes efficiency in production lines.

Moreover, the introduction of high-speed spindles and powerful motors has revolutionized the cutting capabilities of CNC routers. This enhancement not only increases material removal rates but also extends the range of materials that can be processed effectively, from soft woods to hard metals.

Additionally, the incorporation of multi-axis technology has allowed for intricate and detailed shapes to be produced, facilitating designs that were previously impossible with traditional machinery. Overall, these technological advancements in CNC router design are not just improving productivity; they are transforming the very essence of manufacturing in various industries.

The Impact of CNC Routers on Precision and Efficiency in Manufacturing

CNC routers have revolutionized the manufacturing landscape, significantly enhancing precision and efficiency across various sectors. According to a report by MarketsandMarkets, the CNC router market is projected to grow from USD 1.22 billion in 2021 to USD 1.73 billion by 2026, indicating a compound annual growth rate (CAGR) of 7.3%. This growth is largely driven by increasing demand for automation and precision tools that can deliver consistent quality at high volumes.

The impact of CNC routers on manufacturing processes is particularly evident in industries such as woodworking, aerospace, and automotive. A study published in the Journal of Manufacturing Processes noted that the implementation of CNC technology reduced material waste by up to 25%, while also increasing production speeds by 30% compared to traditional methods. Such advancements not only optimize operational workflows but also enable manufacturers to achieve tighter tolerances, with accuracy levels often reaching within 0.01 mm. This enhanced precision allows for more intricate designs and improved product performance, setting a new standard in the manufacturing industry.

Applications of CNC Routers Across Various Industries

The demand for efficient and precise material processing solutions is driving the adoption of CNC routers across various industries, particularly in automotive, electronics, and aerospace. These sectors require advanced manufacturing technologies to enhance productivity and precision, making CNC routers critical for achieving modern production standards. As highlighted in the recent industry reports, the global CNC router market is anticipated to grow significantly, reflecting a broader trend towards automation and smart manufacturing.

In addition, the upcoming 2025 Munich Shanghai Electronics Production Equipment Exhibition serves as a critical platform for showcasing innovations in electronic intelligent manufacturing. This event underscores the transformative impact of technologies like fiber lasers, which enhance the capabilities of CNC routers, enabling manufacturers to meet the stringent requirements of emerging industries, such as electric vehicles. The anticipated growth in the machine tool market—projected to reach $229.46 billion by 2032 with an 8.1% CAGR—further emphasizes the pivotal role that CNC routers play in the current manufacturing landscape.

Tips: When selecting a CNC router, consider the specific materials and applications you’ll be working with to ensure optimal performance. Additionally, staying updated on industry trends can help businesses make informed decisions regarding equipment investments that align with future demands.

Future Trends in CNC Router Technology and Their Implications for Manufacturing

The future of CNC router technology is poised for remarkable advancements that will significantly impact manufacturing processes. As industries increasingly demand precision, flexibility, and efficiency, CNC routers are evolving to incorporate advanced features like artificial intelligence and automation. These innovations not only enhance machining capabilities but also contribute to sustainable manufacturing practices, fostering a circular economy.

Tips: Consider investing in CNC routers that offer multi-axis machining centers to boost precision in complex geometries. Embrace automation features that can streamline production processes, reducing downtime and minimizing waste.

With the global woodworking machinery market projected to grow significantly over the next decade, the implications for manufacturers are profound. The integration of modern technologies will drive productivity and creativity, enabling businesses to adapt to changing consumer preferences. By leveraging these advancements, manufacturers can create more customized products while optimizing resource usage.

Tips: Stay updated on the latest CNC technology trends to remain competitive. Collaborate with technology providers to explore innovative design and production methods that align with sustainable practices.

The Evolution of CNC Routers in Modern Manufacturing

This chart represents the increase in adoption of CNC routers in various manufacturing sectors from 2015 to 2023. The data illustrates the trends in percentage growth across different industries, highlighting the impact of CNC technology.

Related Posts

-

How to Choose the Best Small CNC Machine for Your Business Needs

-

How to Optimize Your Production Efficiency with Fast CNC Machining Techniques

-

Exploring CNC Router Innovations at 2025 China Import and Export Fair 138th Session

-

Understanding the Benefits of 5 Axis Machining for Modern Manufacturing Processes

-

5 Smart Tips for Choosing the Right Small CNC Mill for Your Business Needs

-

Innovative Solutions for Your Small CNC Machine Needs