Blog

Why Fast CNC Machining is Essential for Modern Manufacturing Efficiency

In today's rapidly evolving manufacturing landscape, the importance of fast CNC machining cannot be overstated. As industries strive for increased efficiency and reduced lead times, the demand for advanced machining solutions that can deliver precision and speed has surged. According to a recent report from the International Federation of Robotics, the global CNC machining market is projected to reach $9 billion by 2025, a clear indicator of the industry's pivot towards automation and rapid production techniques. Fast CNC machining stands at the forefront of this transformation, enabling manufacturers to swiftly respond to market demands while maintaining the highest quality standards.

Expert insights further emphasize the critical role of fast CNC machining in enhancing operational efficiency. Dr. Emily Chen, a renowned authority in manufacturing technologies, states, "Fast CNC machining not only cuts down production time but also improves product accuracy, which is vital in competitive markets." This statement highlights the dual benefits of rapid machining processes: they not only speed up production cycles but also ensure that the final products meet stringent quality requirements, thereby minimizing wastage and enhancing profitability.

As companies increasingly adopt fast CNC machining, the industry will likely witness a shift towards more advanced methodologies and technologies that prioritize speed without compromising on quality. This evolution will be pivotal in driving manufacturing efficiency and setting new benchmarks for success in the global market.

The Definition and Importance of Fast CNC Machining in Manufacturing

Fast CNC machining has emerged as a cornerstone of modern manufacturing efficiency, fundamentally redefining production timelines and output quality. By leveraging advanced CNC (Computer Numerical Control) technologies, manufacturers can achieve rapid prototyping and short lead times with extraordinary precision. According to a report by the International Federation of Robotics, the implementation of CNC machining has increased manufacturing productivity by approximately 30% over the past decade, allowing firms to respond swiftly to market demands and enhance their competitive edge.

The importance of fast CNC machining lies not only in its speed but also in its scalability and adaptability across various industries. For instance, a study by McKinsey & Company highlights that companies utilizing fast CNC processes gain a 20% reduction in costs associated with delays and inefficiencies. This capability enables manufacturers to produce complex components with intricate designs at unmatched speeds while maintaining strict adherence to quality standards. As industries increasingly embrace the digital transformation, fast CNC machining stands at the forefront, affirming its role as a vital enabler of operational excellence and innovation in manufacturing.

Why Fast CNC Machining is Essential for Modern Manufacturing Efficiency

| Process Type | Average Production Time (hrs) | Material Efficiency (%) | Cost per Unit ($) | Tolerance Level (mm) |

|---|---|---|---|---|

| CNC Milling | 3.5 | 90 | 45 | 0.05 |

| CNC Turning | 2.0 | 85 | 30 | 0.03 |

| CNC Laser Cutting | 1.5 | 95 | 60 | 0.01 |

| CNC Waterjet Cutting | 2.5 | 92 | 50 | 0.02 |

| CNC Plasma Cutting | 2.8 | 88 | 40 | 0.04 |

Key Benefits of Fast CNC Machining for Production Efficiency

Fast CNC machining has become a pivotal element in modern manufacturing, significantly enhancing production efficiency. One of the key benefits of this technology is its ability to reduce lead times. Traditional machining methods can be time-consuming, often leading to delays in project timelines. In contrast, fast CNC machining streamlines the production process, enabling manufacturers to produce components quickly and respond to market demands swiftly.

Additionally, fast CNC machining improves precision and consistency in manufacturing. With advanced computer numerical control systems, manufacturers can achieve high levels of accuracy, resulting in parts that meet exact specifications. This not only reduces the need for rework and adjustments but also enhances product quality. As a result, companies can maintain competitive advantage through reliable and superior products.

Tip: To maximize the benefits of fast CNC machining, ensure that your designs are optimized for the machining process. This includes simplifying geometries where possible and selecting suitable materials that can be processed quickly without compromising quality.

Tip: Consider investing in training for your team on the latest CNC technologies and software. Keeping your workforce skilled will ensure that your production remains efficient and that the machines are utilized to their full potential.

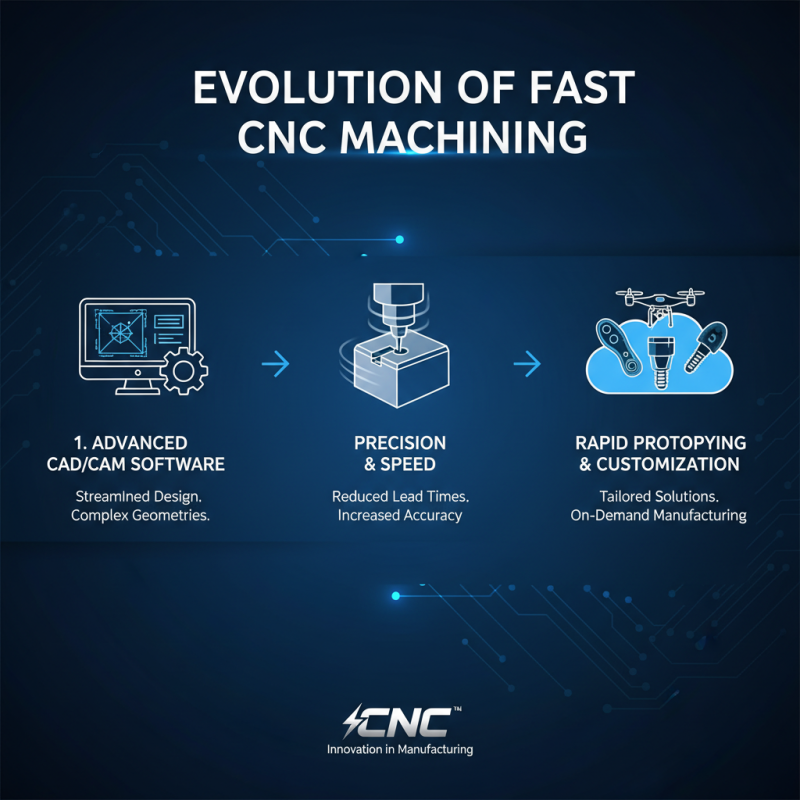

Technological Innovations Driving Fast CNC Machining Forward

The evolution of fast CNC machining is fundamentally linked to a series of technological innovations that have revolutionized the manufacturing landscape. Advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software have streamlined the design process, allowing engineers to create complex geometries with ease and precision. These tools enable manufacturers to reduce lead times significantly while increasing the accuracy of the final products, thereby meeting the growing demand for rapid prototyping and customized solutions.

Moreover, the integration of artificial intelligence and machine learning into CNC machining systems has further accelerated production processes. These technologies facilitate real-time monitoring and optimization of machining parameters, leading to enhanced efficiency and reduced waste. As machines become increasingly autonomous, manufacturers can achieve higher throughput without sacrificing quality. Additionally, innovations in materials and tooling technologies contribute to faster machining speeds and improved surface finishes, enabling companies to remain competitive in a fast-paced market. These advancements highlight the vital role that technology plays in driving fast CNC machining forward, ultimately enhancing overall manufacturing efficiency.

Comparison of Fast CNC Machining with Traditional Manufacturing Methods

Fast CNC machining has revolutionized the manufacturing landscape by providing a level of efficiency and precision that traditional manufacturing methods often struggle to achieve. Unlike conventional methods, which may rely on slower processes and manual intervention, CNC machining uses computer-aided design (CAD) to automate operations. This not only speeds up production but also enhances the consistency and quality of the finished products. The precision offered by CNC machines means that intricate designs can be realized with minimal waste, significantly reducing costs and improving timelines for manufacturing.

**Tips:** To ensure optimal results in CNC machining, it’s crucial to select the right materials and cutting tools for your project. Investing in high-quality tools can lead to better finishes and longer machine life, which in turn contributes to overall production efficiency.

When comparing fast CNC machining to traditional methods, one of the most significant advantages is the reduction in lead time. Traditional manufacturing often involves lengthy setup times and labor-intensive processes, whereas CNC machines can quickly switch between different tasks and configurations. This flexibility allows manufacturers to respond quickly to market demands and customize orders efficiently. Additionally, the ability to produce complex shapes without the need for extensive tooling means that designers can push the boundaries of creativity without worrying about production feasibility.

**Tips:** Keep in mind that proper maintenance and regular training for operators are key to maximizing the advantages of CNC machining. A well-maintained machine performs better and lasts longer, while skilled operators can fully harness the technology's potential to enhance productivity.

Comparison of Fast CNC Machining with Traditional Manufacturing Methods

Future Trends in Fast CNC Machining and Their Impact on Industry

As industries seek to enhance productivity and reduce lead times, the future of fast CNC machining is poised to bring transformative changes. One key trend is the integration of advanced automation technologies, which enables machines to operate with minimal human intervention. This shift not only accelerates production cycles but also enhances precision and reduces the likelihood of errors, thus improving overall manufacturing efficiency.

Another significant trend is the adoption of cloud computing and the Internet of Things (IoT) in CNC machining processes. By connecting machines to cloud platforms, manufacturers can monitor performance in real time, analyze data for optimizations, and make informed decisions to streamline operations. This connectivity paves the way for predictive maintenance, reducing downtime and ensuring that machinery operates at peak efficiency for longer periods.

Additionally, the emphasis on sustainability is reshaping the landscape of CNC machining. Enhanced processes aim to minimize waste and energy consumption, aligning manufacturing practices with environmental stewardship. As companies adopt these practices, the future of fast CNC machining will not only impact operational efficiency but also contribute to a greener industry, proving that technological advancement and sustainability can go hand in hand.

Related Posts

-

How to Optimize Your Production Line with Fast CNC Machining Solutions

-

How to Optimize Your Production Efficiency with Fast CNC Machining Techniques

-

Exploring the Future of CNC Machining Parts in Modern Manufacturing Techniques

-

How to Choose the Best Small CNC Machine for Your Business Needs

-

Understanding the Benefits of 5 Axis Machining for Modern Manufacturing Processes

-

The Evolution of CNC Routers Transforming Modern Manufacturing Processes