Blog

Top 10 Precision CNC Machining Tips for Optimal Production Efficiency

In today's competitive manufacturing landscape, achieving optimal production efficiency is paramount, particularly in the realm of precision CNC machining. This technology has revolutionized industries by providing unparalleled accuracy and repeatability in part production. According to a recent report by the International Manufacturing Technology Show (IMTS), precision CNC machining can increase production efficiency by up to 30% when best practices are applied. As manufacturers strive to reduce waste and enhance their operational capabilities, understanding the intricacies of CNC machining becomes crucial.

Industry experts emphasize the importance of adopting strategic approaches to maximize the benefits of precision CNC machining. Dr. Emily Rhodes, a leading figure in CNC technology, states, "Embracing precision machining not only enhances product quality but also significantly streamlines the manufacturing process." This insight aligns with data indicating that companies utilizing precision CNC machining techniques experience a 25% reduction in lead times and a marked improvement in overall project timelines. As we delve into this topic, we will explore the top ten tips that can help businesses harness the full potential of precision CNC machining, ensuring they remain at the forefront of efficiency and productivity.

Understanding CNC Machining and Its Importance in Modern Manufacturing

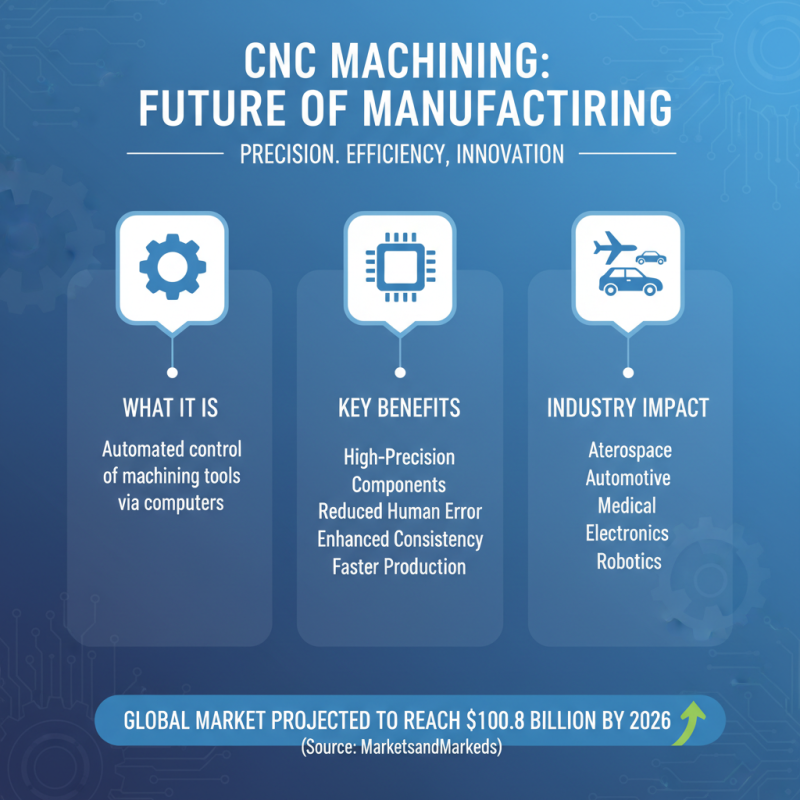

CNC (Computer Numerical Control) machining stands at the forefront of modern manufacturing, enabling companies to produce high-precision components with impressive efficiency. This automated technology allows for the meticulous control of machining tools through programmed computer commands, significantly reducing human error and enhancing product consistency. According to a report by MarketsandMarkets, the CNC machining market is projected to reach USD 100.8 billion by 2026, reflecting its critical role in industries ranging from aerospace to automotive.

The importance of CNC machining is underscored by its ability to cater to complex designs and high-volume production demands with unmatched precision. A study published in the Journal of Manufacturing Science and Engineering highlights that CNC machining can achieve tolerances as tight as ±0.005 mm, making it an invaluable process for creating intricate parts that meet rigorous engineering specifications. Furthermore, the integration of advanced machining techniques, such as multi-axis machining and additive manufacturing, is further propelling the capabilities and applications of CNC technology in today's fast-paced production environments. This evolution not only enhances operational efficiency but also supports the growing trend towards customization in manufacturing, enabling businesses to respond quickly to market changes and client demands.

Key Factors Affecting Precision in CNC Machining Processes

Precision in CNC machining is paramount for achieving optimal production efficiency, and several key factors play a critical role in ensuring this precision. One of the foremost elements is the machine setup, which must be meticulously calibrated. According to a report by the International Journal of Advanced Manufacturing Technology, improper setup can result in dimensional errors exceeding 0.1 mm, leading to wasted materials and extended production times. Ensuring that the CNC machines are accurately aligned and that the tooling is correctly installed can mitigate these issues and enhance overall output quality.

Another significant factor affecting precision is the choice of materials. The mechanical properties of the material can impact machinability, which subsequently affects the quality of the machined components. A study published in the Journal of Manufacturing Processes indicated that the variations in modulus of elasticity and tensile strength among different materials can lead to a variation in tolerance levels. It is essential for engineers to select appropriate materials that not only support the desired specifications but also interact favorably with the machining processes in place. Additionally, maintaining optimal cutting speeds and feeds is crucial, as inadequate settings can lead to tool wear and thermal effects that compromise precision, often resulting in a decrease in the operational lifespan of the machines.

Top 10 Precision CNC Machining Tips for Optimal Production Efficiency

This bar chart illustrates the key factors affecting precision in CNC machining processes and their estimated impact on production efficiency. Each factor contributes differently to the overall machining efficiency, highlighting areas for potential optimization.

Best Practices for Tool Selection and Maintenance in CNC Operations

In the realm of CNC operations, tool selection and maintenance are pivotal elements that directly influence production efficiency. Choosing the right cutting tools can greatly enhance machining accuracy and reduce cycle times. When selecting tools, consider factors such as material compatibility, tool geometry, and coating options, as these can significantly affect the performance and lifespan of tools. Always align the tool specifications with the specific demands of the project to ensure optimal results.

Regular maintenance of CNC tools is equally important to sustain their effectiveness and efficiency. Implementing a routine inspection schedule helps identify wear and damage early, preventing subpar machining outcomes. Additionally, proper storage of tools when not in use can protect them from environmental factors that could lead to rust or degradation. Incorporating cleaning protocols after each use also extends tool life and ensures consistent performance.

To further boost productivity, consider adopting advanced technologies such as tool monitoring systems. These systems provide real-time feedback on tool condition and performance, allowing for proactive adjustments. By marrying best practices in both tool selection and maintenance with innovative technologies, manufacturers can achieve remarkable efficiency in CNC machining operations.

Techniques for Optimizing Machine Setup and Calibration Procedures

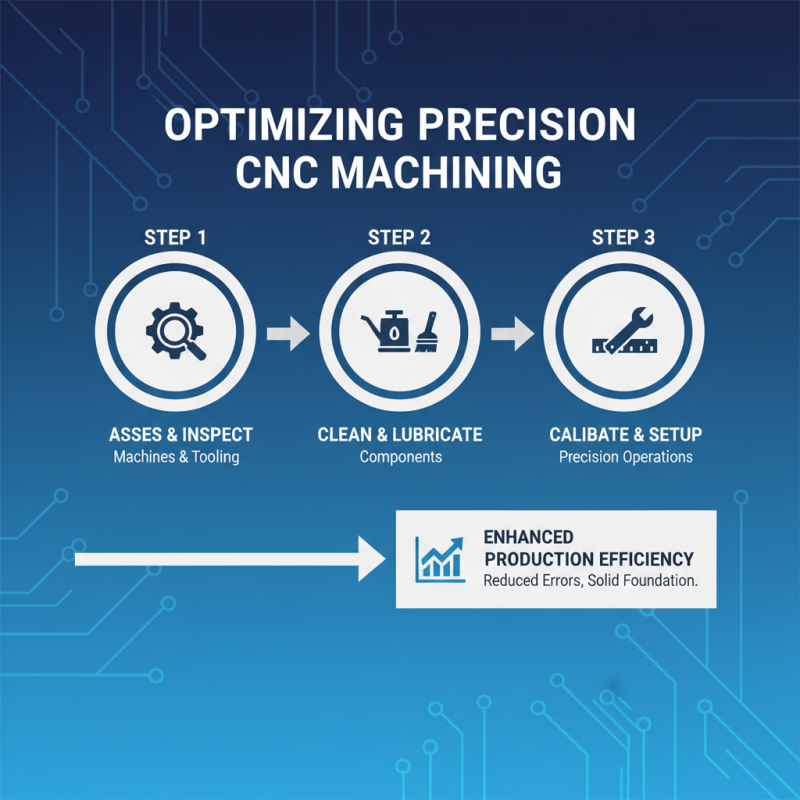

When it comes to optimizing machine setup and calibration procedures in precision CNC machining, a systematic approach is key to enhancing production efficiency. Start with a comprehensive assessment of your machines and tooling systems. Ensure that all components are clean, properly lubricated, and free from wear or damage. This initial step establishes a solid foundation for precision operations, reducing potential errors during the manufacturing process.

Next, implement a consistent setup protocol that minimizes variability. Use detailed setup sheets that outline specific configurations for different jobs, including tool selection, offset adjustments, and workpiece fixtures. In addition, embrace the use of digital calibration tools and software to monitor machine performance regularly. By routinely verifying alignment and calibration, you can identify issues early, reducing downtime and maintaining high-quality standards. These practices not only promote optimal machine performance but also enhance overall workflow, saving time and resources in the production cycle.

Strategies for Improving Workflow and Reducing Downtime in CNC Production

In the world of CNC machining, optimizing workflow and minimizing downtime are crucial for maximizing production efficiency. One effective strategy is to implement a robust preventive maintenance program. Regularly scheduled maintenance not only helps to identify potential issues before they escalate but also ensures that all machines operate at peak performance. By routinely inspecting and servicing machinery, manufacturers can significantly reduce unexpected breakdowns, which can lead to costly downtimes.

Another key aspect of improving workflow lies in the organization and setup of the workspace. Streamlining the layout of machines and tools can greatly enhance accessibility and reduce the time operators spend searching for equipment. Incorporating lean manufacturing principles, such as minimizing waste and optimizing processes, can lead to smoother operations. Additionally, investing in training programs for operators ensures that they are proficient in using the technology and can troubleshoot minor issues on the spot, further decreasing the likelihood of production halts. By fostering a culture of continuous improvement and efficiency, manufacturers can create a sustainable environment that reduces downtime and maximizes output.

Related Posts

-

Unlocking the Secrets of Fast CNC Machining for Efficient Production

-

Uncovering the Advantages of Utilizing CNC Machines in Modern Manufacturing

-

Understanding the Role of CNC Lathe Machines in Modern Manufacturing

-

Innovative Solutions for Your Small CNC Machine Needs

-

How to Optimize Your Production Line with Fast CNC Machining Solutions

-

How to Optimize Your CNC Router Machine for Maximum Efficiency