Blog

Top 10 CNC Machining Parts You Need for Your Next Project

In the world of manufacturing, precision and efficiency are paramount, and CNC machining parts play a crucial role in achieving these goals. As noted by industry expert, Dr. Emily Carter, “The quality and design of CNC machining parts can significantly influence the success of any project.” This statement underscores the importance of selecting the right components when embarking on a new venture.

CNC machining, or computer numerical control machining, allows for high-level precision in producing complex parts from various materials. Understanding which CNC machining parts are essential for your next project can streamline the production process, reduce costs, and improve the overall quality of the final product. From custom brackets to intricate gears, each part fulfills a vital function in the assembly and operation of machines, making it imperative to carefully consider which ones you will need.

In this article, we will explore the top 10 CNC machining parts that are indispensable for your upcoming project. Whether you are a seasoned engineer or a DIY enthusiast, having a solid grasp of these components will enhance your ability to create high-quality products that meet both performance and design standards.

Essentially Required CNC Machining Parts for Optimal Project Efficiency

When embarking on a new project that requires CNC machining, selecting the right parts is essential for achieving optimal efficiency. High-quality CNC machined parts not only enhance the functionality of your project but also contribute to its overall success. Among the most crucial parts to consider are precision components such as custom brackets, gears, and housings. These parts are designed to meet the exact specifications needed for your application, ensuring better performance and reliability in operation.

Additionally, pay attention to the integration of support components, such as fasteners and spacers, which play a vital role in the assembly and stability of the final product. The use of high-grade materials for these parts is imperative, as they often bear the stress and strain during operation. By choosing the right CNC machining parts, you enable smoother workflows and minimize potential downtimes resulting from substandard components. Investing in quality machining parts not only streamlines the production process but also paves the way for future scalability, making it a fundamental step in any successful project.

Top 10 CNC Machining Parts for Optimal Project Efficiency

Key Factors to Consider When Selecting CNC Machining Parts

When selecting CNC machining parts for your next project, several key factors need to be considered to ensure optimal performance and compatibility. First, material selection plays a crucial role, as it directly influences the durability and functionality of the end product. According to industry reports, aluminum and stainless steel are among the most popular materials used in CNC machining due to their excellent strength-to-weight ratios and resistance to corrosion. Moreover, the choice of material can affect the machining process, cycle times, and overall cost, with certain materials requiring more intricate machining processes that can increase lead times.

Another vital aspect is the precision specifications required for your project. High-precision components typically require more advanced machinery and tooling, which can significantly impact both the cost and timeframe of production. As per the findings from a recent technical publication, projects demanding tolerances within ±0.005 inches may necessitate investing in high-end CNC machines equipped with superior cutting tools. Furthermore, considering the complexity of the part geometry is essential, as intricate designs may require more setup time and specialized skilled labor. Understanding these parameters can help streamline the production process and achieve the desired quality standards while keeping costs manageable.

Top Industry Applications for CNC Machined Components

CNC machining plays a crucial role in various industries, facilitating the production of intricate parts with high precision and efficiency. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $117.2 billion by 2026, at a CAGR of 5.4%. This growth is driven by the increasing demand for high-quality components in sectors such as aerospace, automotive, and medical.

In the aerospace industry, CNC machined components are essential for producing parts that adhere to stringent safety and performance standards. Advanced materials, including titanium and aluminum alloys, are commonly machined to create lightweight, durable components like brackets, housings, and structural elements. A report from Research and Markets indicated that the aerospace CNC machining market is expected to grow substantially, fueled by the ongoing advancements in aircraft design and the rising demand for fuel-efficient planes.

Similarly, the automotive sector relies heavily on CNC machining for the production of engine components, transmission parts, and interior fixtures. The growing trend towards electric vehicles (EVs) further amplifies this demand, as these vehicles require precision-engineered components to optimize performance and reliability. According to the International Energy Agency, global EV sales are set to exceed 8 million units in 2023, indicating a significant opportunity for CNC machining applications tailored to support this evolution in automotive technology.

Top 10 CNC Machining Parts You Need for Your Next Project

| CNC Machining Part | Material | Industry Application | Tolerance |

|---|---|---|---|

| Brackets | Aluminum | Automotive | ±0.01 mm |

| Spacers | Plastic | Electronics | ±0.05 mm |

| Gears | Steel | Industrial Machinery | ±0.02 mm |

| Covers | Titanium | Aerospace | ±0.03 mm |

| Housings | Aluminum | Consumer Electronics | ±0.01 mm |

| Connectors | Copper | Telecommunications | ±0.02 mm |

| Mounting Plates | Stainless Steel | Construction | ±0.05 mm |

| Aluminum Frames | Aluminum | Furniture | ±0.03 mm |

| Pipes | Plastic | Plumbing | ±0.1 mm |

| Custom Parts | Varies | Various | ±0.01 - ±0.1 mm |

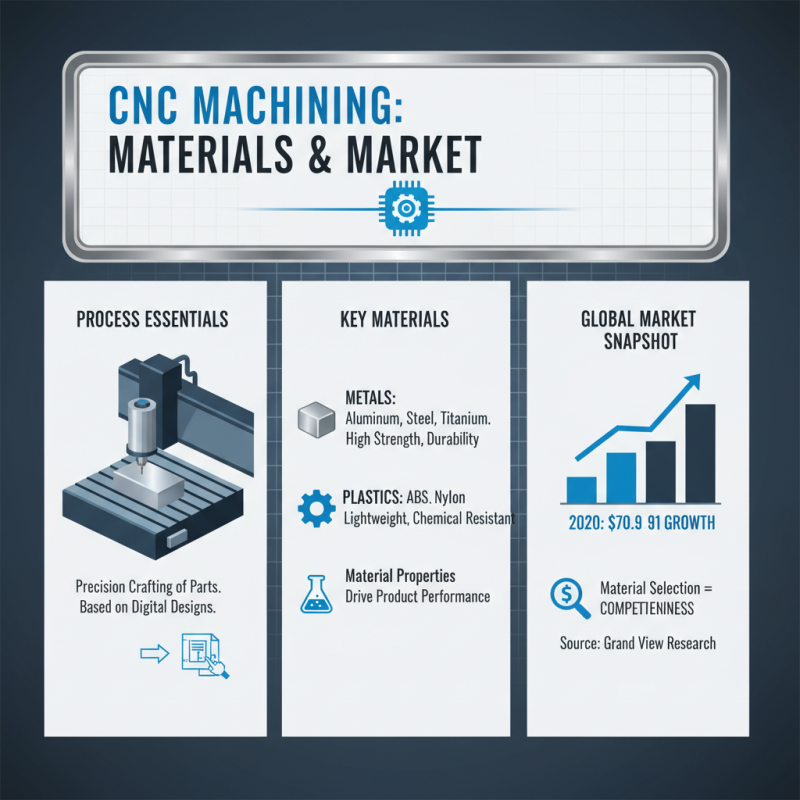

Comparative Analysis of Materials Used in CNC Machining Parts

CNC machining is a pivotal process in modern manufacturing, allowing for the precision crafting of parts from a variety of materials. When selecting materials for CNC machining, the properties of the material play a crucial role in determining the performance and durability of the final product. Common materials include metals such as aluminum, steel, and titanium, along with plastics like ABS and nylon. According to a report by Grand View Research, the global CNC machining services market was valued at approximately $70.91 billion in 2020 and is projected to expand, emphasizing the essential role material selection plays in competitiveness.

Aluminum is favored for its lightweight properties and excellent machinability, making it ideal for automotive and aerospace applications. Corrosion resistance and high strength-to-weight ratio contribute to its popularity, with a projected growth rate of 5.2% in the aerospace sector alone, as noted by the Aerospace Industries Association. On the other hand, materials like stainless steel are celebrated for their durability and resistance to wear, presenting a preferred choice in the medical and food processing industries. A report from MarketsandMarkets highlights that the stainless steel CNC machining market is expected to grow significantly, driven by increasing demand for high-quality, durable components in critical applications.

In comparison, plastics such as PVC and polyethylene offer cost-effective alternatives with specific advantages in terms of insulation and chemical resistance, making them suitable for electronic applications. However, as noted by ScienceDirect, they exhibit limitations in strength and thermal resistance compared to metals. It is crucial for engineers and project managers to conduct a thorough comparative analysis of these materials to ensure optimal material selection aligns with project specifications and operational demands.

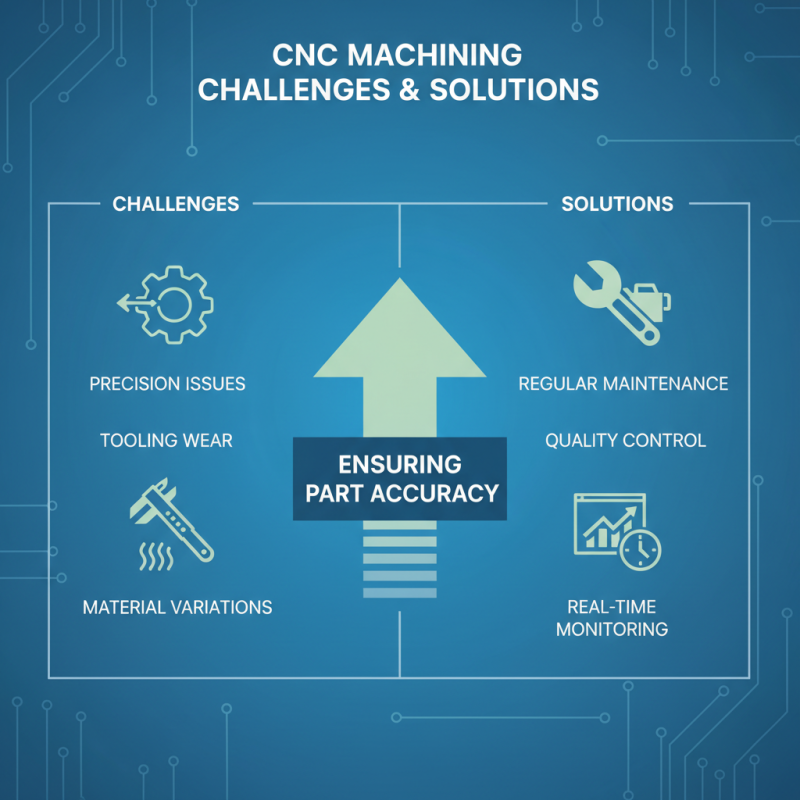

Common Challenges in CNC Machining and How to Overcome Them

CNC machining is a vital process in modern manufacturing, but it comes with its share of challenges. One of the most common issues is the precision of the parts being produced. Variations in material properties, tooling wear, and machine calibration can lead to discrepancies in the final dimensions of the components. To tackle this, maintaining regular machine maintenance is crucial. Implementing a rigorous quality control process, including real-time monitoring and feedback mechanisms, can help detect inconsistencies early, allowing for prompt adjustments and ensuring that parts meet required specifications.

Another significant challenge is managing production time and costs. Delays often stem from setups, tool changes, and the unavailability of materials. Adopting lean manufacturing principles can optimize workflows and minimize waste. Utilizing advanced scheduling tools can help to streamline operations, while establishing reliable supplier relationships ensures a steady supply of necessary materials. By strategically planning the production process and incorporating flexibility in scheduling, manufacturers can effectively reduce lead times and costs while maintaining high-quality output.

Related Posts

-

Exploring the Future of CNC Machining Parts in Modern Manufacturing Techniques

-

How to Choose the Best Small CNC Machine for Your Business Needs

-

How to Optimize Your Production Efficiency with Fast CNC Machining Techniques

-

The Evolution of CNC Routers Transforming Modern Manufacturing Processes

-

Top 5 Axis CNC Mill Buying Guide for 2025 Essential Features and Tips

-

Why Fast CNC Machining is Essential for Modern Manufacturing Efficiency